154. Stocker, A. S Jan. 18.

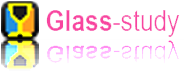

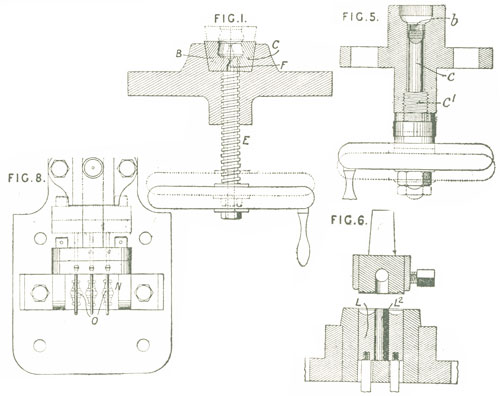

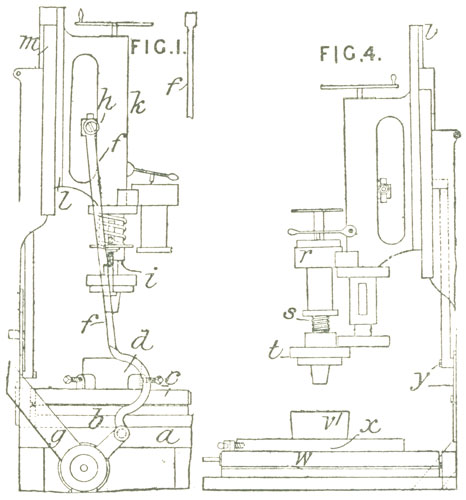

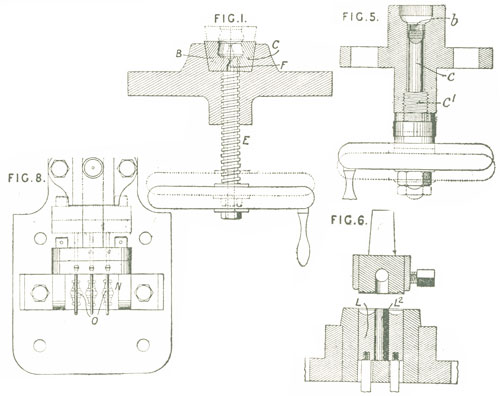

Moulding. - Relates to the manufacture, by means of dies in a fly-press or otherwise, of caps or stoppers, unions, and shields for feeding-bottles, the apparatus being also applicable for making pots or jars, table and chair castor balls, and bedstead furniture, in glass, porcelain, or similar materials. Fig. 1 shows an arrangement for moulding a cap for a feeding-bottle. The matrix is made in two parts B, C fitted in a conical recess in a bed-plate. The upper die is forced down into the matrix by a plunger. The air escapes through a hole F. The finished article is discharged by raising the matrix by means of a screw B so that the parts can be separated. In another arrangement, the bottom of the matrix is separate from the sides, which are forced together or moved apart by right and left handed screws. Fig. 5 shows a machine for making a stopper or cap with a screw on its end, such as is described in Specification No. 1149, A.D. 1871, [Abridgment Class Stoppering &c.]. The screw-thread on the stopper is formed by forcing the plastic material into an internally-screwed ring b forming part of the matrix.

This ring is fixed to a spindle c having a threaded portion c1, the pitch of which is equal to that of the screw b. By rotating the spindle c, the screwed ring can be withdrawn from the moulded article. Fig. 6 shows an arrangement for moulding a shield for a feeding-bottle. The plunger L2 serves to guide the matrix L, and also to make the central perforation in the shield. The moulded shield is discharged by raising the matrix L by means of a treadle. Fig. 8 shows a plan of a machine for moulding unions for feeding-bottles. The articles are first moulded solid by compressing the material between a lower die N and a similar upper die, and the holes are then formed through them by passing pins O horizontally through the moulds ; the pins are carried by a plunger suitably guided and actuated. These unions may be formed with stems, to facilitate firing and glazing, the stems being fitted in holes in clay slabs in which they are supported during firing. The clay slabs or saggers may be moulded between dies in a press, the lower die being lifted to discharge the finished slab.

|