3616. Webb, T. G. Nov. 27.

|

Finishing; cutting glass. —

Relates to means for removing, from tumblers, goblets, wine-glasses,

and other vessels or articles, the portions of glass which are attached

to the blowing-iron. The separation is effected either by means of a

diamond tool, or by a wire heated by an electric current. In the

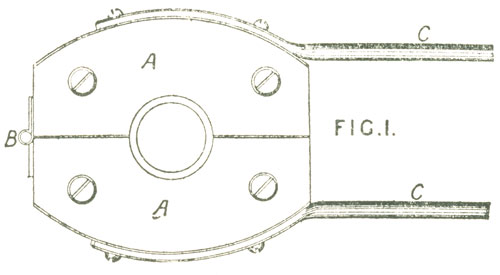

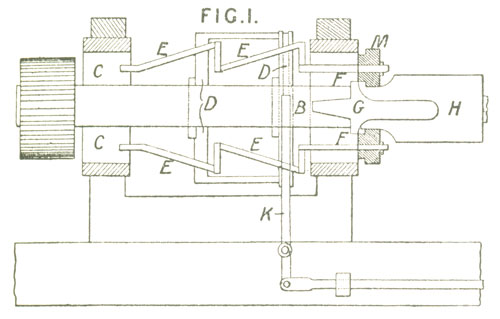

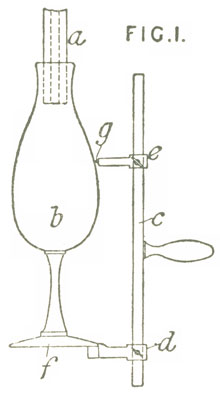

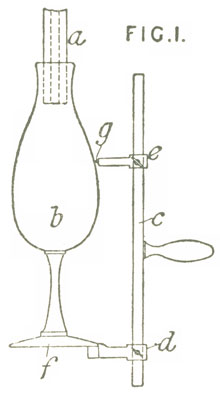

arrangement shown in Fig. 1, the wine-glass b, while attached to the blowing-iron a, is secured by its foot f to a stand c carrying a diamond point g. The wine-glass is then cut off by rotating the iron

by hand, so that the tool presses against the glass with sufficient

pressure to produce a cut. The arms d, e, carrying the foot and the tool respectively, are adjustable on the standard c. In

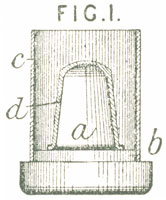

a modification, the foot of the wine-glass is clamped centrally on a

revolving table, the frame of which carries a standard with two spring

diamond-holders pressing against the glass. In another form, the

wine-glass is supported, foot upwards, in a spring frame known as a

"gadget." The diamond is mounted on one prong of a forked piece, the

other prong of which carries a roller. The glass is inserted between

the diamond and roller, and by means of a screw the prongs of the fork

are brought near together, so that both diamond and roller press on the

glass. The forked piece is adjustably mounted on a revolving table. In

a fourth form, the foot of the wine-glass is mounted in a headstock on

a frame similar to a lathe bed, and the end to be cut off is held by a

spring clamp. The diamond is held elastically in a slide-rest or by

other means, and the wine-glass is rotated by a hand-wheel. When a

heated wire is used, the wine-glass is held as described above in a

revolving table, and is turned round in contact with the wire, which is

of platinum &c. and extends partly round the periphery of the

article. The article is generally cut cold, and the operation may be

performed after it has been separated from the blowing-iron. The cut

edges are afterwards glazed by heat.

Punties; moulding and pressing. —

Punties and moulds or "plugs" for blowing and pressing glass are formed

of or coated with gold, silver, platinum, iridium, palladium, or

rhodium, or alloys thereof. The alloy known as iridio-platinum is

preferably used.

|