2257. Hue, L. V., and Rozière, C. Aug. 5.

Moulding; pressing; ornamenting. — The required designs are impressed upon the glass when almost in a state of fusion, by means of punches or stamps with or without colours, and other pieces of hot glass are welded on, thus producing articles with smooth exterior surfaces and interior

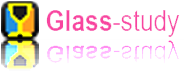

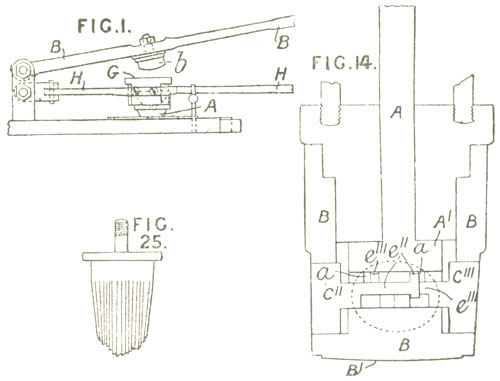

ornamentation. Fig. 1 shows a press for forming knobs for doors &c. The molten glass is placed in a matrix A, and the engraved stamp b is

impressed thereon by means of the lever B. A covering-piece of glass,

moulded to the required shape and size, is placed while very hot over

the matrix, and is welded to the ornamented glass by pressure of jaws

G, operated horizontally by levers H. A similar knob &c. may be

produced by stamping the design in the interior of a blown cylinder

while in the mould, and afterwards bending the edges towards each

other, so that the ornamentation is enclosed in a hollow knob.

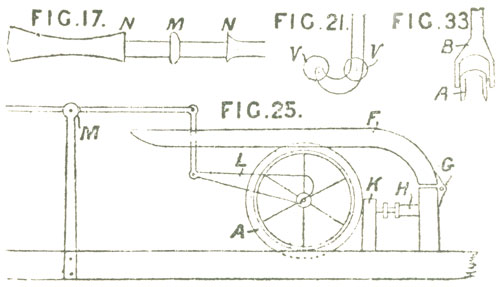

Paper-weights, baluster knobs, &c. may be similarly ornamented. In some cases, for ornamenting decanters, smelling-bottles, drinking-glasses, vases, &c., a cast-iron box B, Fig. 14, is used, containing engraved stamps C11, C111, &c. having tail-pieces e11, e111, &c., which catch into slots a in a foot-piece A1 on a screw rod A. The box B, which may be engraved on the bottom B1

and may be also grooved or fluted, is lowered by means of a press into

a matrix containing the glass, which is almost fused. The rod A is then

turned, and the foot A1 drives out the stamps C11, C111,

&c., thus ornamenting the glass. By turning the rod A in an

opposite direction the stamps are withdrawn, after which the box B is

removed. A piece of white or coloured glass of the required size and

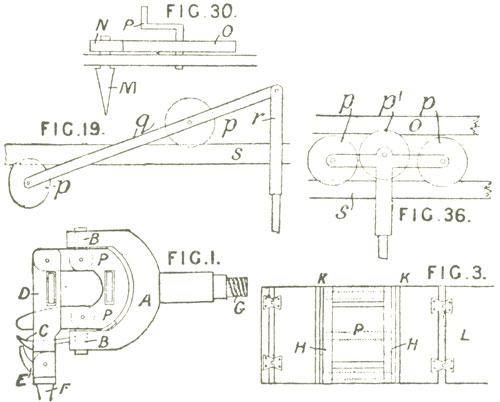

shape is then placed within the matrix and welded to the ornamental glass. Fig. 25 shows a stamp suitable for ornamenting tubes for decorating rooms, &c. In

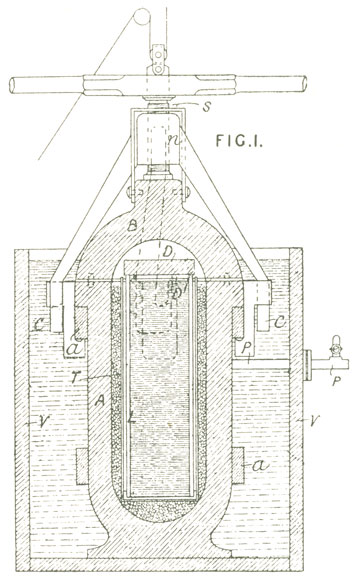

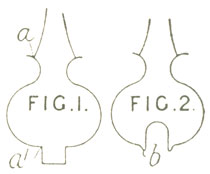

forming lustre plates or "fiddle drops," the mould is made in two parts

connected together by a strong hinge. Each half carries a matrix in

which the glass is placed, to be ornamented by stamps. After the stamps

are withdrawn, the halves of the mould are brought together, by

pressing a handle, and the halves of the plate are thus welded

together. According to the Provisional Specification, the process may

also be applied to the manufacture of lamp globes, salt cellars,

inkstands, terminal ornaments for bedsteads, curtain rods, water

bottles, inkstands, &c.

|